ADVANTAGE

SIX FEATURES

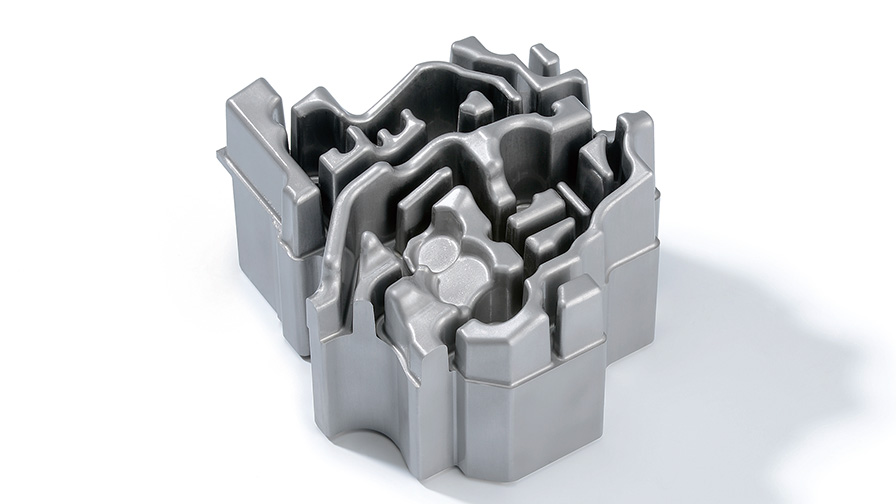

We design and are produce a die-casting die.

First the product is designed by the latest CAD system. The product is processed using CAM system and NC equipment based on the design. And the product is delivered after check of three-dimensional testing equipment and an inspector.

We can respond to all customer's needs from a trial-product to mass-product goods.

The level of Quality for our products is higher than before.

So we use a CAD/CAM system to make a perfect product.

Our product is managed strictly by a system from a design to production.

We keep challenging.

We try to give the form to customer's needs.

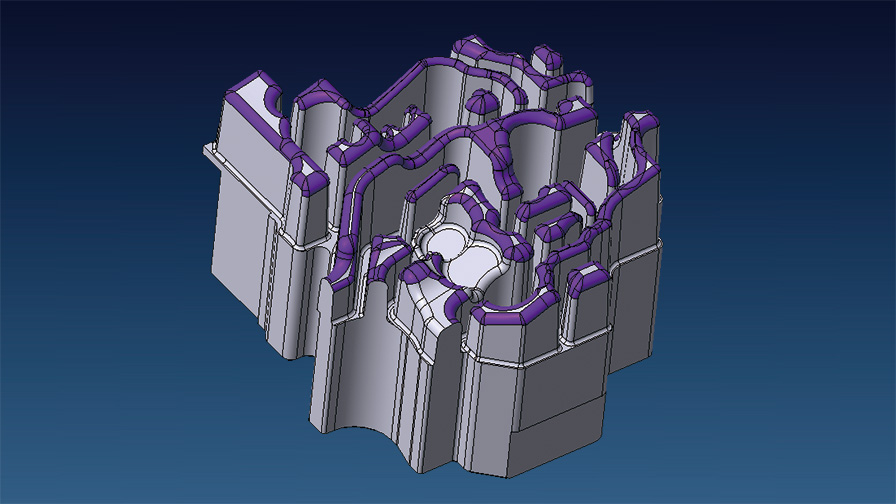

The latest CAD/CAM system is introduced to respond to the various and complicated needs.

And system engineers are being educated. Therefore a better product can be drafted.

We introduce a large machine aggressively.

That's to respond to the customer's various needs.

A professional engineer takes charge of the each machines to maintain the product quality. We do the effort into which the use of the machine is expanded.

All Diecasters and die-builders use different CAD system. But we would like to propose STEP and Parasolid, to transfer data. Because the data does not always translate accurately. DYNAMO prefers to use STEP and Parasolid. (Please contact us. We can handle CATIA and UG, Pro-E, Solidworks & Iges)

We prefer to use direct hard milling.

Minimum end mill size is Ø0.5mm and the machine is 20000 rpm/s. Where possible the insert is machined without EDM, removing the need for polishing the recast layer and re-tempering the part, increasing the shot life of the insert.