BUSINESS

Diecast Maintenance

As part of our effort to shorten the maintenance work period, we at Nihonseiki have introduced a non-contact 3D measuring machine. For small-scale maintenance, we can measure the data in a non-contact way without disassembling the molds/dies entrusted to us from our customers. Since our skilled worker can repair manually based on the measured data, we can finish maintenance work in a shorter period than ever before. At the time of delivery, we provide assurance to the maintenance completed molds/dies in a non-contact way, so that they are ready for immediate casting work upon delivery. We also have many processing machines as well, so that we can accept large-scale maintenance including molds and dies manufactured by our competitors.

Welding

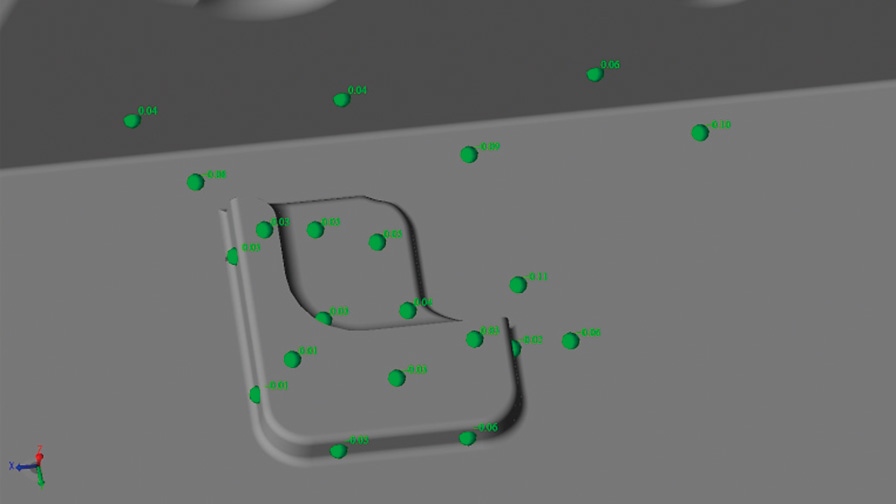

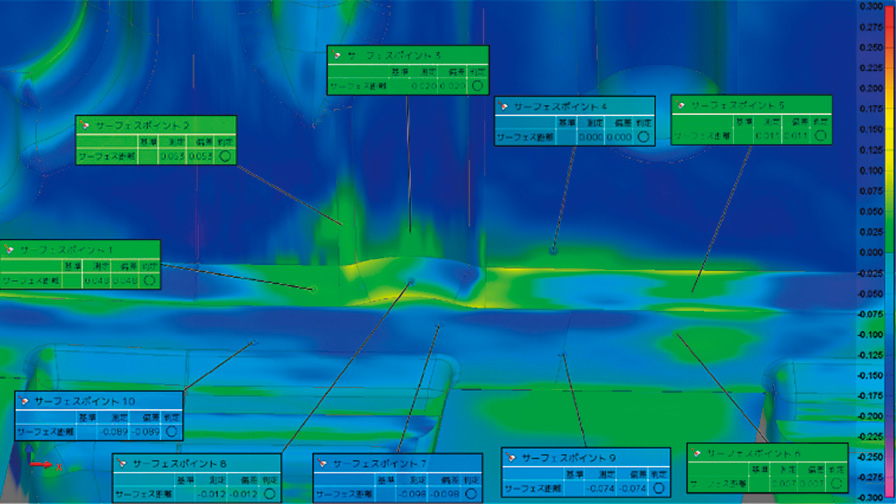

Non-contact 3D measurement

Small-scale maintenance

(without machining)

- Meeting about repair contents

- Receiving a repair mold/die

- Welding (manual finishing)

- Polishing

- Inspection

- Delivery

We measure the data in a non-contact way without disassembling the mold / die.

Since no disassembling / reassembling work is required, this way of maintenance can shorten the delivery time.

- Compliance with unexpected orders for maintenance

- Quality assurance in a non-contact way of measurement

Large-scale maintenance

(with machining)

- Meeting about repair contents

- Receiving a repair mold/die

- Disassembling the mold/die

- Welding

- Machining

- Polishing

- Inspection

- Reassembling the mold/die

- Delivery

- Integrated operation in series from disassembling to welding, machining, polishing, reassembling and inspection

- No need of labor by our customers in disassembling, etc. during the maintenance work

- Delivery of mold/die in the reassembled state for immediate casting work upon delivery

- Quality assurance with non-contact or contact-copying 3D measuring machine